Nestfield is a top tier technology company in Korea and has advanced data solutions for smart manufacturing. We are able to provide solutions for digital transformation and interconnection to a global data ecosystem for your business. Our solutions are mostly based on standardized technologies such as Asset Administration Shell (AAS), Time Sensitive Networking (TSN), 5G MEC (Multi-access Edge Computing), etc., and we are continuously evolving with emerging new technologies.

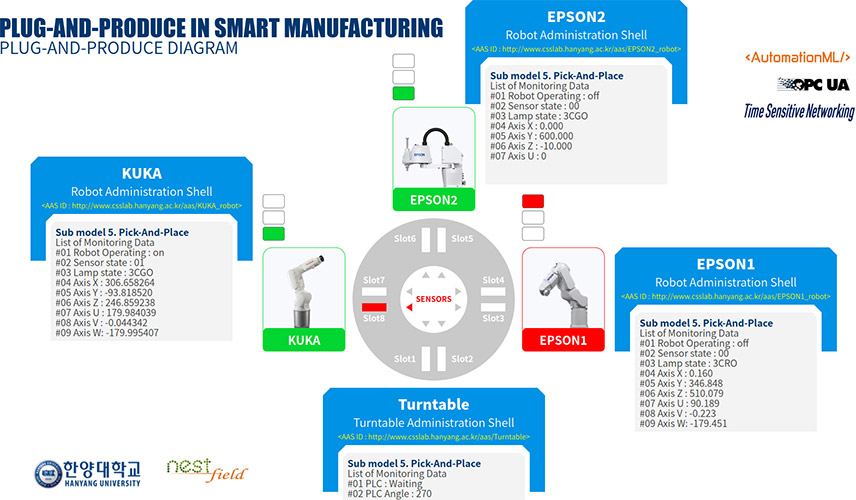

We have developed an AAS-based plug-and-produce (PnP) testbed of industrial field devices to implement an I4.0 scenario. PnP is one of the use cases for adaptable factory.

Physical Assets in real world

Physical Assets in real world Asset Administration Shell (AAS) in digital world

Asset Administration Shell (AAS) in digital worldNestfield has developed an AAS-based PnP testbed (with three robots and one turntable) to implement an I4.0 scenario of Plug-and-Produce (i.e., a representative use case of adaptable factories).

OPC UA/TSN technologies were implemented to realize the interoperability between different assets.

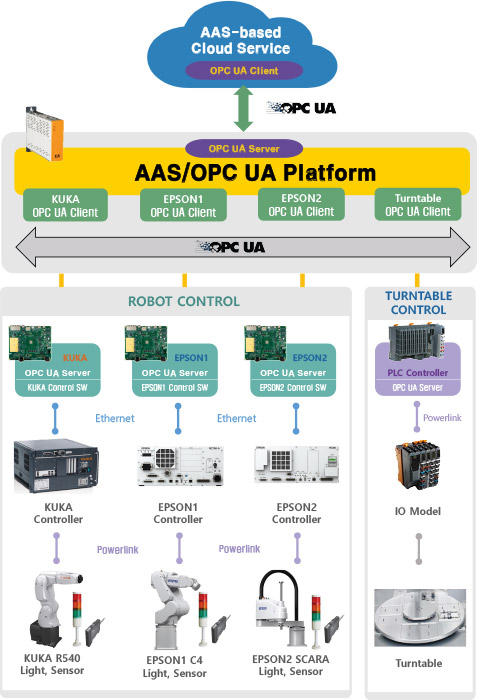

Cloud Layer

A Web UI can control the operation of the PnP system, and demonstrate the AAS data of the system in real time.

Platform Layer

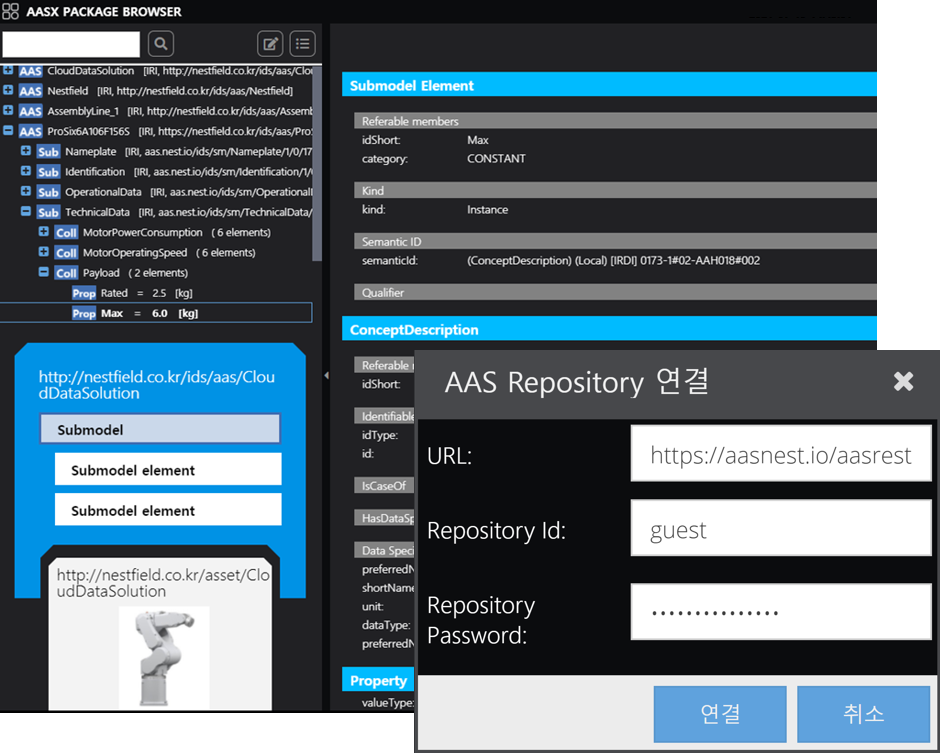

AASX Package Explorer [1] was used as the tool to create the information model for describing AAS data.

OPC UA realizes the interoperability among the robots and the turntable and serves as the AAS communication interface.

TSN guarantees real-time and deterministic data transmission for AAS communication.

Field Layer

Vendor-independent Assets (i.e. robots and turntable) cooperate to realize the PnP operation.

[1] Admin-Shell-io/Aasx-Package-Explorer (2021). Available from https://github.com/admin-shell-io/aasx-package-explorer Plug-and-Produce system architecture

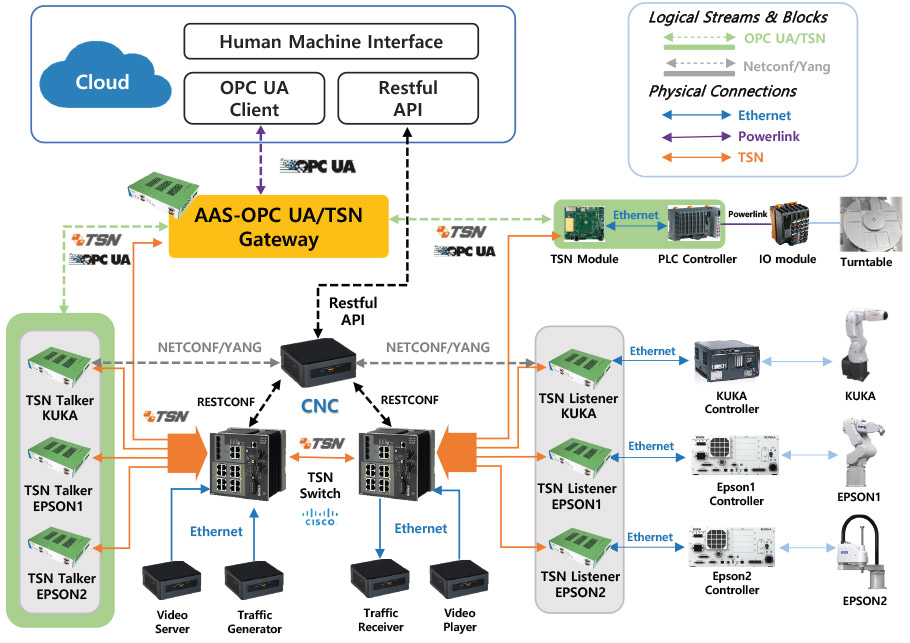

Plug-and-Produce system architectureCloud Layer

provides a web-based Human-Machine Interface(HMI) to demonstrate and operate the entire TSN-based Robot Control System.

Communication layer

employs AAS-OPC UA/TSN to provide real-time service to exchange robot control commands and status feedback with TSN end-stations.

Field layer

contains various industrial facilities (e.g., TSN switches, TSN end-stations, Linux PC, industrial robots and turntable) for TSN-based robot control and turntable operation.

Access Nestfield YouTube Channel for more details : https://www.youtube.com/nestfieldchannel TSN System Architecture

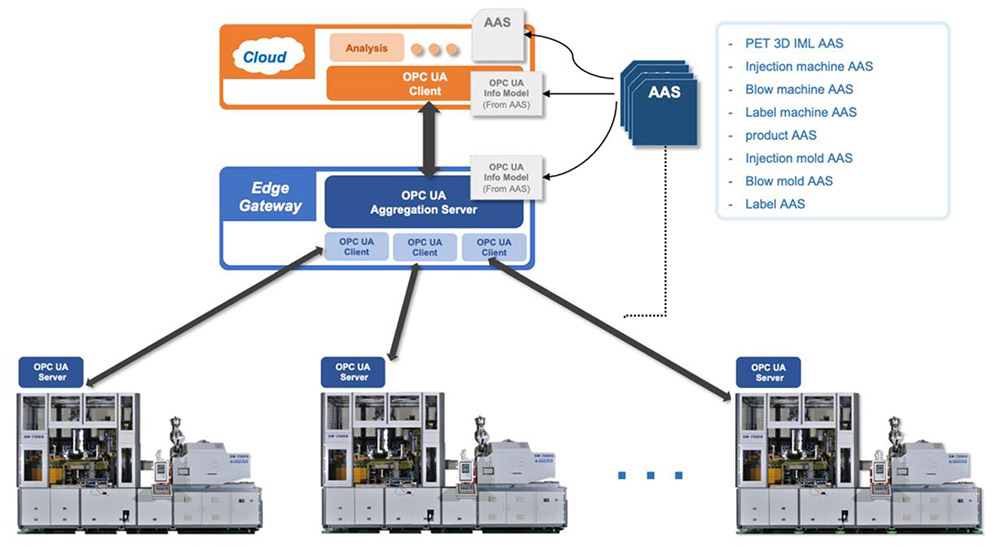

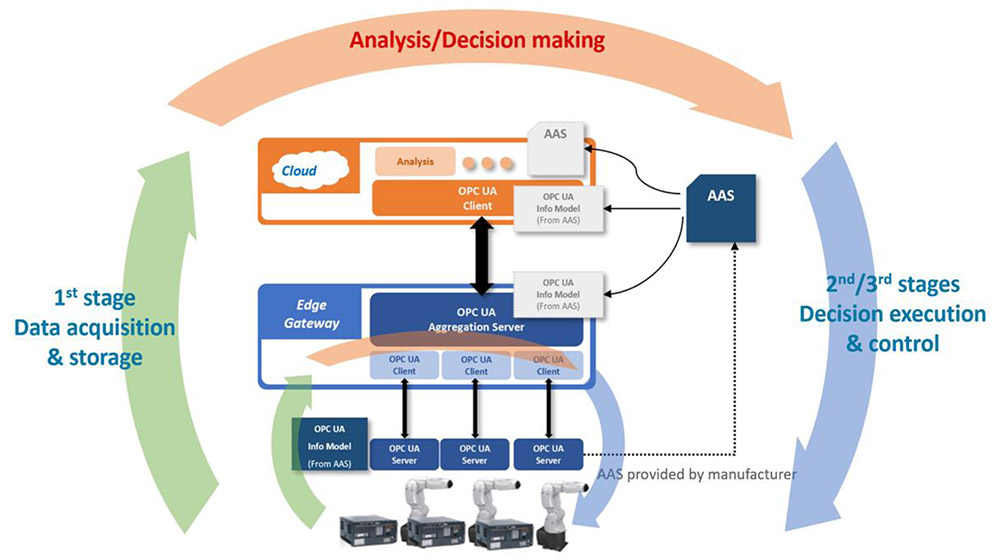

TSN System ArchitectureNestfield developed an AAS-based pilot plant with the support of the Korean Ministry of SMEs and Startups, and KOSMO (Korea Smart Manufacturing Office).

During the 1st stage of the Pilot Plant Project (PPP) in 2020, an AAS-based data acquisition and storage system was developed and successfully installed in two pilot plants, i.e., Shinwoo Costec and Huons.

In the 2nd stage of the PPP, we plan to expand the development of AAS-based standard technologies to the entire life cycle of the production process, including commissioning, operation, management, predition, decision-marking, control, etc.

The 1st AAS-based Pilot Plant in Shinwoo Costec [1]

The 1st AAS-based Pilot Plant in Shinwoo Costec [1] AAS-based data acquisition, storage, analysis, decision-making & execution [1]

AAS-based data acquisition, storage, analysis, decision-making & execution [1]Nestfield developed a new specification about AAS REST API. This specification enables distributed AASs and severs as the foundation for AAS interactions. AASnest.io acts as an AAS Repository that can be accessed through AAS REST API with the user authentication function provided by openIDC.

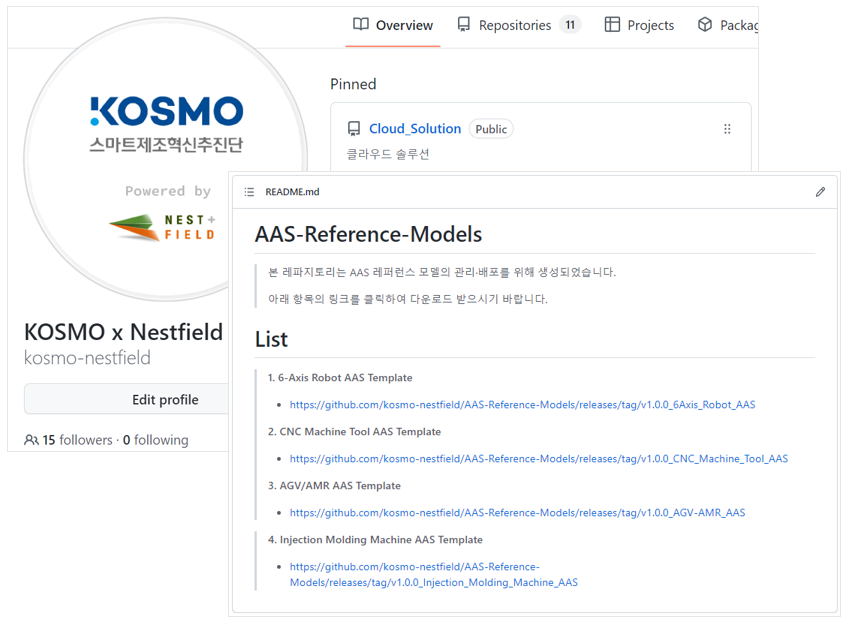

The AAS reference models and related information have been shared via an open GitHub site created by Nestfield & KOSMO.

Nestfield Co., Ltd electric vehicle solutions cover many areas, including the vehicle battery (i.e., the key component of electric vehicles), the diagnostic software for vehicle inspection and an integrated management solution that connects all vehicles. Nestfield’s customer-friendly solutions can be easily applied to your platforms.

Electric Vehicle is currently another big industry area. Nestfield has been investing on electric vehicle related technologies and now can provide the first commercial EVCC (Electric Vehicle Charging Controller) product. EVCC moderates & exchanges data between vehicle and charging station. Now the EVCC product supports DIN70121 specification and IEC15118 will be supported in the near future.

As the electric vehicle market is growing, battery power efficiency and stability become more important. Nestfield manufactures and supplies a battery monitoring system that can check the condition of the battery and manage it to maintain in the best condition.

Nestfield was founded based on traditional control network technologies and IoT technologies, which is the main motivation for Nestfield to apply the latest IT technologies to traditional industry solution. Nestfield's REMS solution collects every vehicle data including vehicle location information, driver's actions, operation and state of devices inside of the vehicle in real-time and upload it to the cloud.

Vehicle control is a high level and vital technology in the process of EV development. Nestfield has been developing EVCU (Electric Vehicle Control Unit) to optimize the control of devices in EV.

In order to monitor/control vehicles, diagnostic solution is essential. Nestfield has EV diagnostic software & data interface module packages for some dedicated EV models. This diagnostic solution is now used in EV maintenance and production.