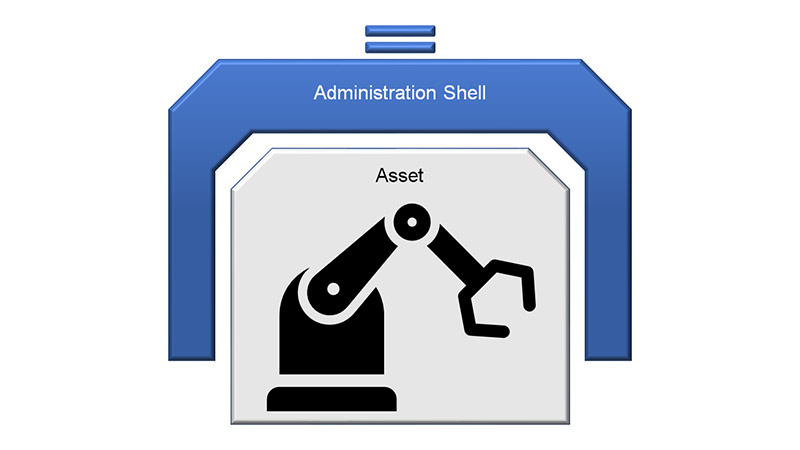

Asset Administration Shell (AAS) AAS is the key technology for digital transformation in Industrie 4.0. Nestfield is the frontier of applying AAS technology in Korea.

Time-Sensitive Networking (TSN) TSN is the most advanced industrial ethernet technology that can make it possible to exchange real-time data and normal traffic streams on the same normal ethernet media. Nestfield has a unique and advanced scheduling algorithm that can optimize the network bandwidth and guarantee real-time data exchange.

OPC UA OPC UA is a most popular and widely used network protocol for exchanging data. It has many advantages for horizontal and vertical integration. Devices can communicate with each other by utilizing OPC UA information models. Nestfield utilizes OPC UA as a basic communication technology in many areas.

Factory Digital Transformation Smart factory & factory digitalization is a hot topic in recent industry areas. Nestfield provides manufacturing data integrating/managing solution that is developed based on standard technologies. Nestfield is continuing activities for digitalization in Korea.

ML-Ops platform (machine learning operation) ML-Ops is a core function of Machine Learning (ML) engineering, which aims to deploy and maintain ML models in production reliably and efficiently. Nestfield is currently preparing an ML-Ops cloud-based platform by adopting industrial solutions.

Anomaly detection platform Anomaly detection is the essential application in smart manufacturing. AI can recognize normal signal patterns from field data and detect unexpected patterns automatically. A lot of AI/ML algorithms can be used to implement anomaly detection. Nestfield has an anomaly detection platform including data acquisition, data processing and machine learning algorithm selection.

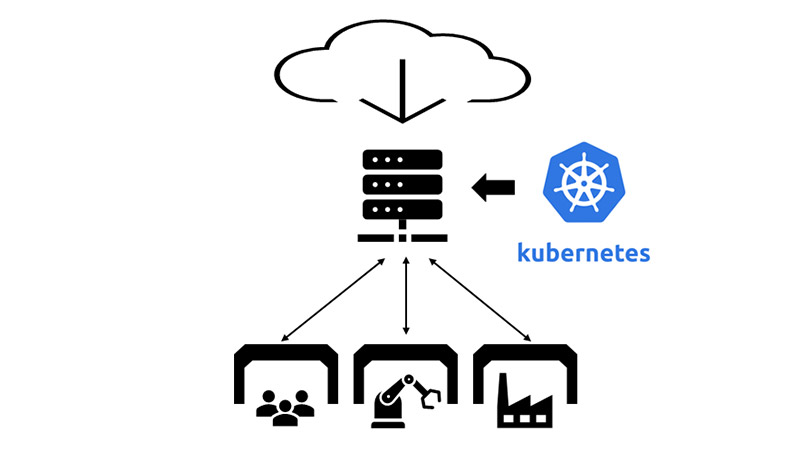

Kubernetes platform Kubernetes is a technology for effective and flexible management to create a scalable cloud and micro service architecture. Nestfield's solutions adopt Kubernetes and provide scalable & stable services.

Sustainable Manufacturing / Product Carbon Footprint Platform industry 4.0 identifies sustainability as a key action for the next decades. Nestfield also has strong interests in digitizing, networking and a sustainable manufacturing industry of the future.

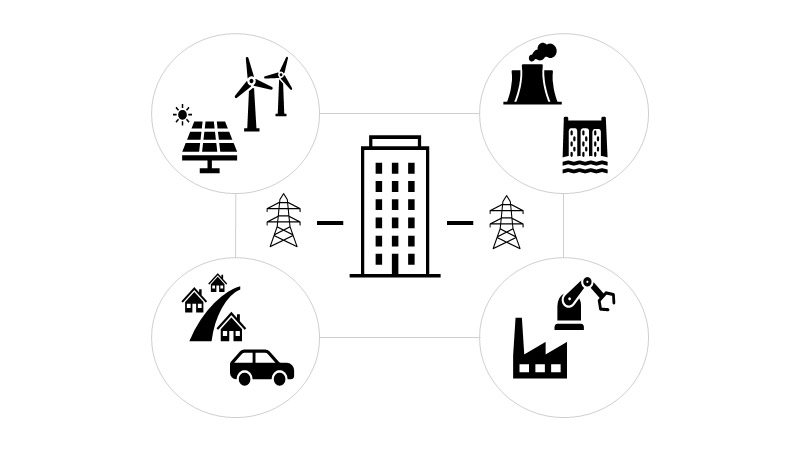

Smart grid demand response DR (Demand Response) is another optimizing technology to reduce energy consumption. Energy providers and consumers interact with each other, based on various ways to manage energy consumption and increase satisfaction. Nestfield has been conducting research on effective and implementable demand response algorithms.

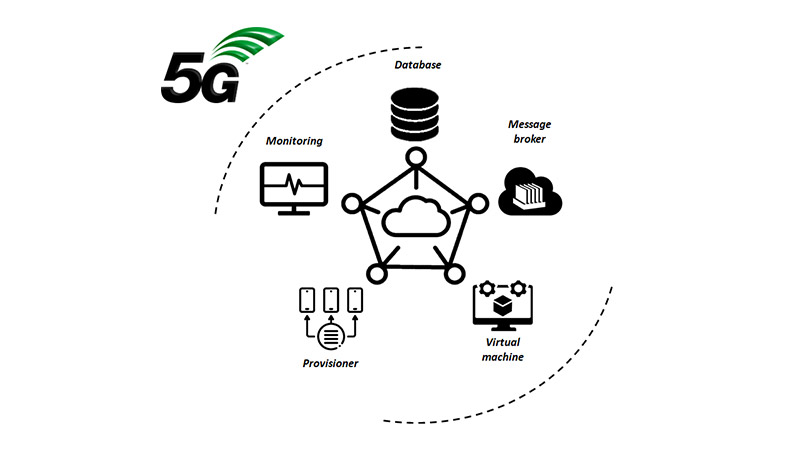

Industrial 5G/5G-MEC 5G is an emerging technology in industry and Nestfield focuses on industrial private 5G technology especially in MEC (Multi-access Edge Computing).

Module Configuration

1. Planning

2. Pre-training

3. Field analysis

1. AAS model creation

2. AAS model conversion

3. AAS model API Server

4. AAS model Repository

1. OPC UA

2. IoT/Message Bus

1. OPC UA

2. Storage Device

3. Management Dashboard

4. IoT/Message Bus

5. High level service interface

1. APP/WEB S/W

2. Intelligence Dashboard (2D)

3. Intelligence Dashboard (3D)

1. OPC UA Field Communication Connection

1. System Maintenance

2. Solution Training

1. Big Data Analysis/prediction solution

2. AI accident prevention prediction solution

3. AR/VR experience Solution

Package Configuration

NIS-Plan 1.0

NIS-Edge 1.0

+NIS-Twin 1.0

NIS-INF 1.0

NIS-Plan 1.0

NIS-Edge 1.0

NIS-Twin 1.0

NIS-INF 1.0

NIS-MRO 1.0

Standard Package

NIS-Cloud 1.0

Standard Package

NIS-Cloud 1.0

NIS-View 1.0

Standard Package

NIS-Cloud 1.0

NIS-View 1.0

NIS-Al 1.0

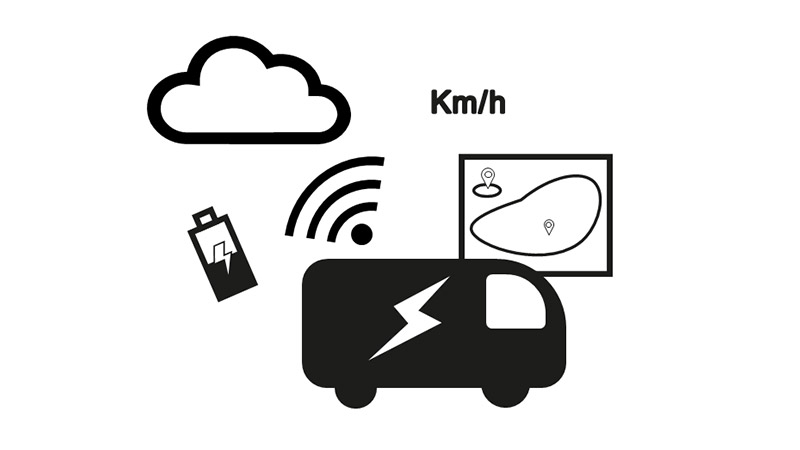

REMS (Remote Monitoring System) We provide a REMS solution that can collect communication data in real time with the help of terminal devices installed in the vehicle. The solution can be managed/analyzed in the central server through an LTE modem or public Wi-Fi.

Currently this solution has been installed on electric buses in Korea.

EVCC (Electric Vehicle Communication Controller) EVCC is a control unit that controls the charging process between the charging station and the electric vehicle battery packs.

It has already been installed on a test vehicle and also passed the field test. Currently we are preparing EVCC for mass production.

SECC (Supply Equipment Communication Controller) A communication controller in the charging station controls the charging process between the power stack and the electric vehicle. The development of a prototype model is currently in progress.

EVCU (Electric Vehicle Control Unit) EVCU is the core device used to control the electric buses. After Nestfield finished the development, we succeeded in verifying the function of EVCU through the test drive of a real vehicle. Next, we plan to test various functionalities of EVCU by carrying out more test drives.

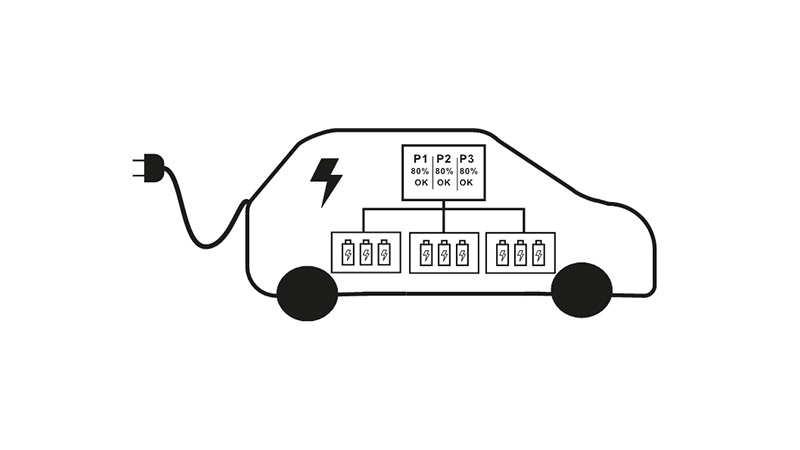

BMS (Battery Management System) This BMS is the key component of the battery system, which controls the electrical condition of the battery and manages its condition for an optimal battery performance.

EV Diagnostic Software Kit This is a vehicle diagnostic software kit that runs on your PC or Android tablet. For connecting it with a vehicle, a wired/wireless diagnostic converter has to be used.

It is currently being used by the vehicle A/S team in Korea.

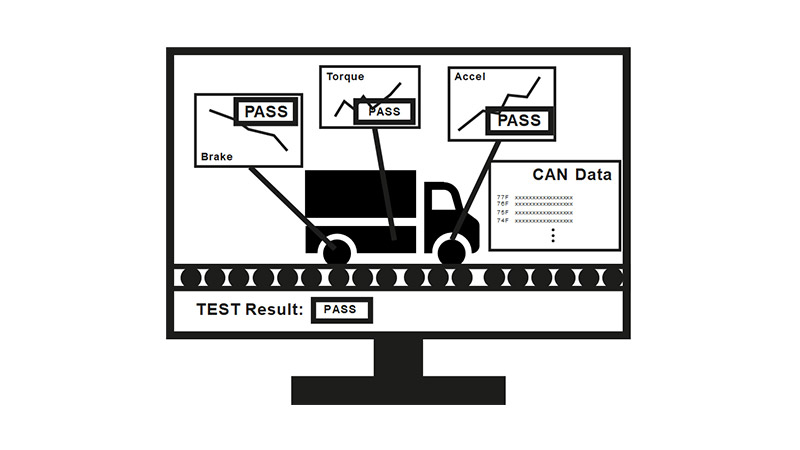

Vehicle Mass Production Inspection Equipment for EOL (End of Line) Testing This product is a vehicle inspection equipment used in the final inspection process of the vehicle production. Dedicated software is applied to each vehicle type.